For this work I am using the Fablight fiber laser cutter. The key to successful metal laser cutting is understanding how the gas, beam, and material interact with each other at the cut location.

I'm initially trying to cut 0.06" 304 type stainless steel. I tested a range of settings:

0.06" 1250Hz 0.25in/s 50% power 130psi

0.03" 1250Hz 0.35in/s 50% power 130psi

0.03" 1250Hz 0.45in/s 50% power 130psi

0.03" 1250Hz 0.25in/s 60% power 130psi

0.03" 1250Hz 0.25in/s 40% power 130psi

0.03" 1250Hz 0.25in/s 50% power 145psi

0.03" 1500Hz 0.25in/s 50% power 130psi

0.03" 1000Hz 0.25in/s 50% power 130psi

The best settings for 0.06" stainless steel

0.03" 1250Hz 0.25in/s 40% power 145psi

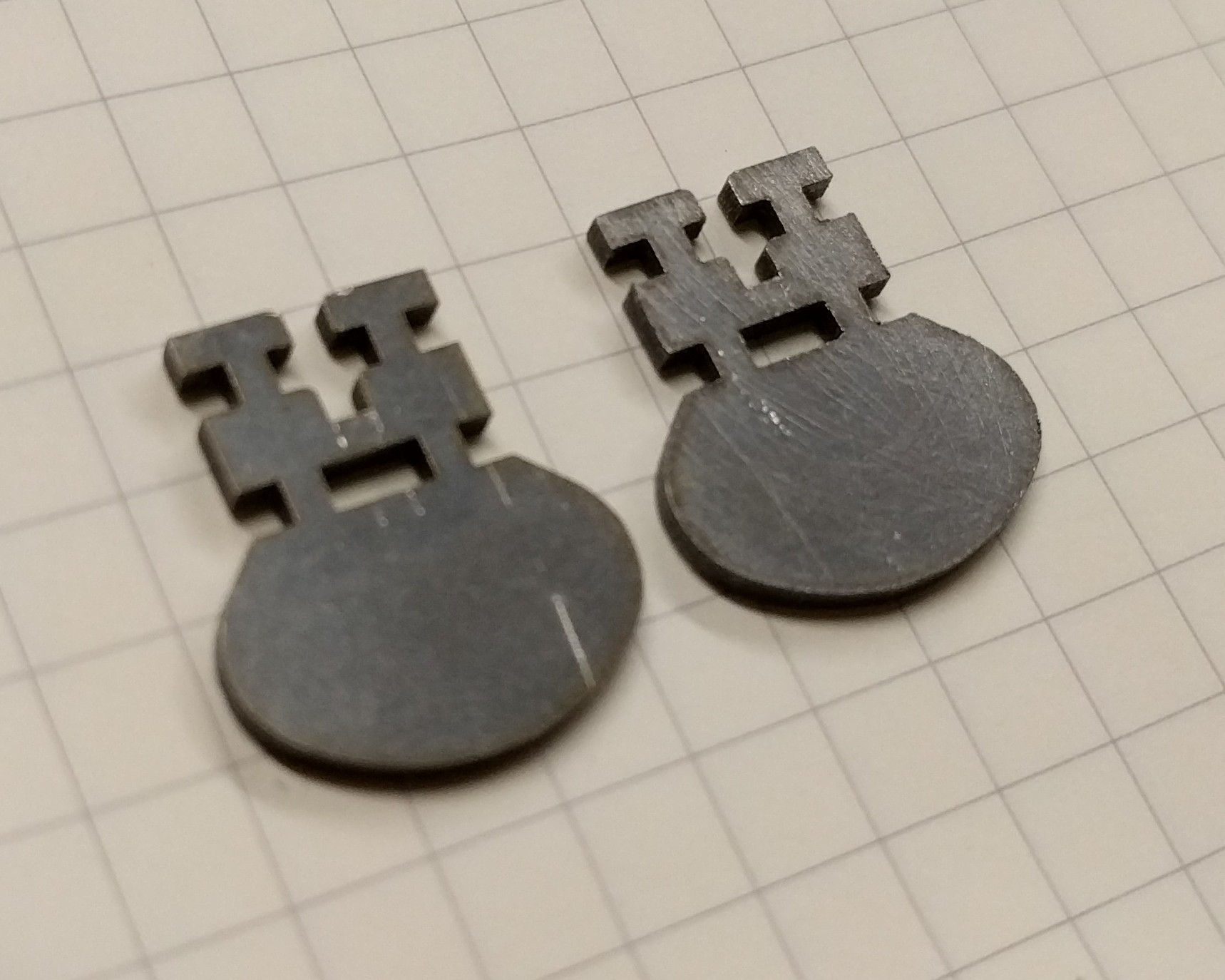

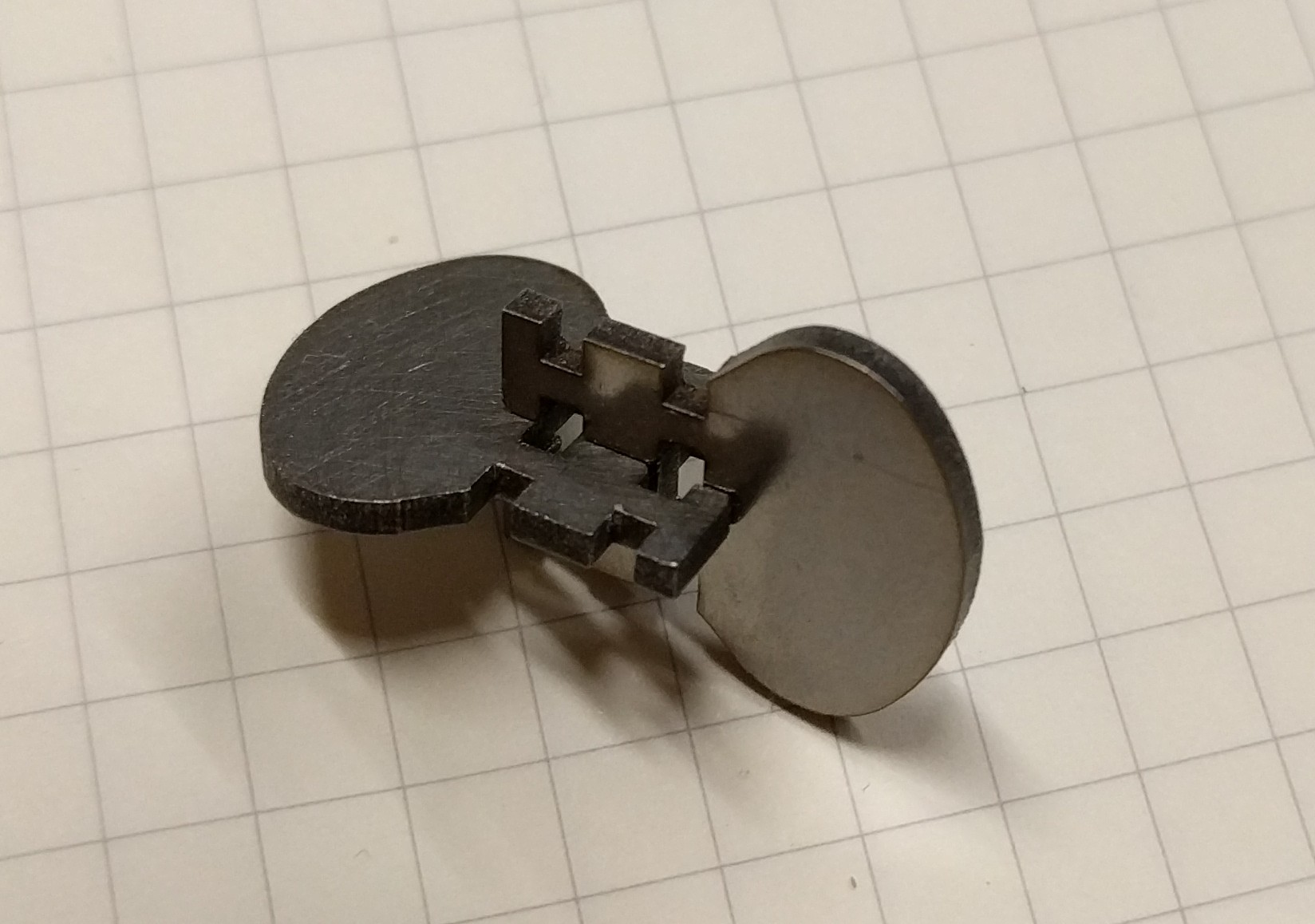

Initial cuts are promising:

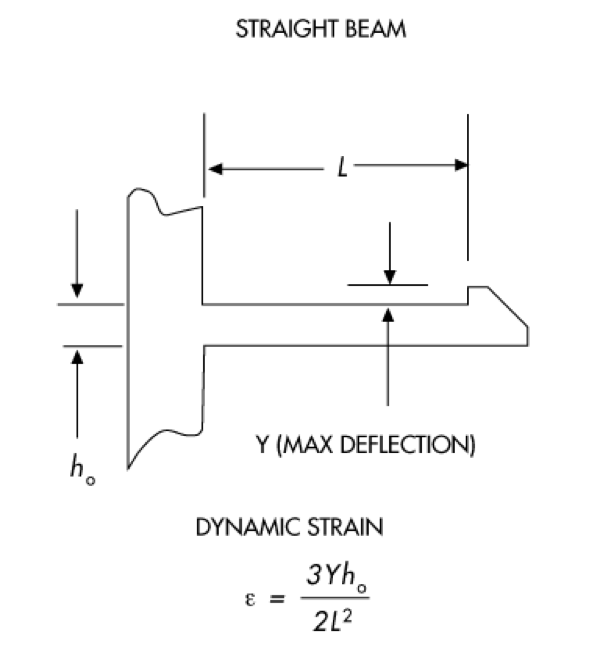

I wasn't using an intelligent method for dimensions of the clip. The following diagram will be helpful. In addition, the fiber laser leaves a fairly rough surface finish along the cutting edge, therefore post processing will be required to reduce friction between the clip and the structural elements.

0.004" is kerf of Fablight, 0.03" waterjet

The kerf of the waterjet is approximately 0.03" and is therefore suitable for these parts. The time to machine a part is ~1 min 50 secs. Still trying to figure out whether the offset specificed in Omax Layout propogates through to Omax Make or whether you need to change it when you open the cut file in Omax Make. Given a target feature size of 3.18mm, a 0.0149 offset created 3.3mm, 0.0125 created a 3.08mm feature size. Therefore the offset should probably be 0.01375. 0.01375 hit the correct dimension however the overall fit was a bit loose, so perhaps use 0.014 and get practcing making clips, or leave it and just get some good clips.